Mach3 Serial Port Plugin Download

Nov 20, 2013 Free Download Mach3 - Allows you to control an industrial or home CNC machine. Kernel Frequency locked at 25kHz (only applicable if using the parallel port driver) Set Next Line function. CNC Software Setup Guide. Do not install the parallel port driver if asked during the installation process. Mach3 Plugins folder. To verify success.

Laser power control via modbus. Mach3 is a great program. People have used it to control a vast diversity of machine, but it has some issues when controlling lasers. This is especially true when it comes to the beam control. The beam can be compared to the spindle of a mill. It does the cutting and has an on/off state and power level (like RPM). On a mill, the spindle can safely stay on during rapid moves above the work and dwell at points without issue.

A laser cannot do that because it does not retract from the material.  It must only be on during G1 feed moves and must not dwell at any point or excessive burning will occur. The normal spindle logic does not work well with lasers. I thought it would be a fun experiment to try to enhance the control using a slave device.

It must only be on during G1 feed moves and must not dwell at any point or excessive burning will occur. The normal spindle logic does not work well with lasers. I thought it would be a fun experiment to try to enhance the control using a slave device.

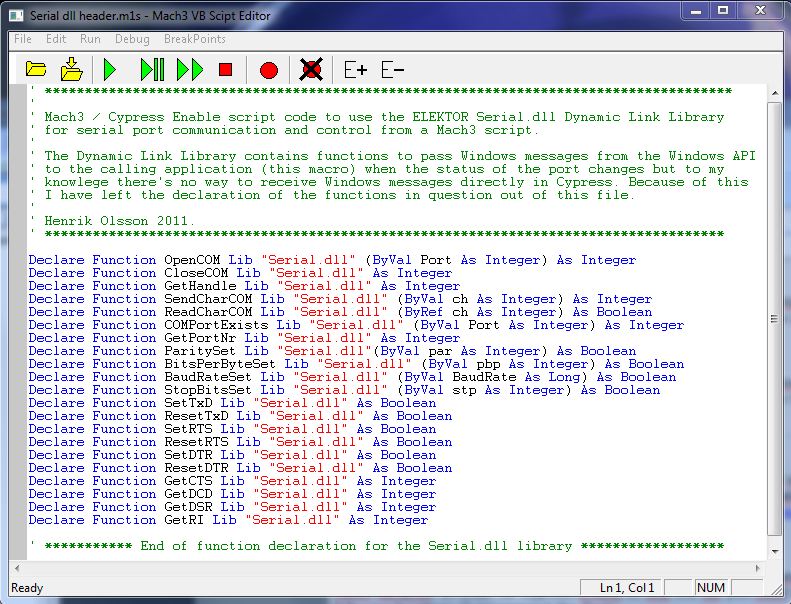

Modbus devices are basically remote device that allow a host to read and write data registers. The remote device can then use the data registers to give information to the host or do a task when a register is written to by the host. The devices typically communicate using a serial port or Ethernet. You can view the. There are a lot of commercial Modbus devices like and the, but I wanted a cheaper home grown version. I thought an would be a good choice because it has a built in USB to serial port, it is less cheap (less than $20) and it is open source. The next change is to add the new M666 line before each first feed move to set the power level.

Photoshop cs5 Patch Adobe Cs5 All Product Activator. By Using Photoshop CS5 amtlib.dll files Crack. Photoshop CS6 32/64-bit amtlib.dll Patch and crack. Adobe photoshop cs5 64 bit amtlib dll crack site torrent.

Begin FIRST_FEED_MOVE “[N]M666 [S]” Next steps The next step is to use a Mach3 feature called “Brains”. This is a ladder logic type programming method that works much faster than macros and can run in parallel with Mach3. This can allow some really interesting ideas. Possible Future Ideas. • Tie power level to feed rate. When a move starts out it accelerates to the desired feed rate. Therefore the power per speed is not constant.

A Brain could adjust for this. • Control beam enable on with “is move G1” logic. Rather than using the E1P1 method common with many laser users, you could have a Brain toggle the beam on whenever the code is in a G1 move. • Return water temp to Mach3.

The Arduino could read water temp and Mach3 could display it on in a DRO. Mach3 could act on a high temperature value and do a feed hold and turn off the beam. • LCD display. The Arduino could control a simple LCD display of feed rates, power levels, axes positions. • Jog buttons. A simple jog button panel could be implemented. • Feed rate offset.

A pot could be used to adjust the feed rate plus or minus while the job is running. • Feed hold with beam off: A feed hold button could be implemented where the motion stop and the beam goes off at the same time.